Today, energy is one of the important and vital data in the life of each person and in almost all production and consumption activities in different economic sectors. During the past decades, due to the ever-increasing population growth , Increasing demand for agricultural products, creating new forms of energy in the agricultural sector and their inappropriate use due to lack of proper management , this economic sector has become an energy-oriented sector and the amount of energy consumption has increased greatly. Scarcity of energy resources and especially the increase in the price of energy carriers in developed countries on the one hand and global warnings and

Examining pistachio dryers and energy consumption in them

sustainable development on the other hand have prompted policymakers to adopt strategies regarding optimal energy consumption in agriculture. In Iran, due to the long-term payment of energy subsidies by the government, the agricultural industry has been preserved in its traditional state, because there was no need to use modern equipment with optimal energy consumption, and subsequently, the necessary motivation for engineers and craftsmen to design the construction of this equipment and the optimization of energy consumption have not been done. It seems that the weak shock caused by the targeting of subsidies has only partially caused confusion because there has not yet been a comprehensive, practical and significant effort to optimize energy consumption, at least in the country's pistachio industry, which may be it is caused by the rising price of pistachios and the cheapness of energy.

But according to the economic situation of the country, this cannot be ignored , because we will inevitably go to the direction where the costs of pistachio production and processing will include a major part of our annual income, , which will question the economic efficiency of pistachio production and processing.

Based on this, if we examine the functioning of energy consumers with a deeper knowledge and vision and measure the costs related to each one, we can take significant measures to improve their performance. .It is obvious that the increase in costs related to a system first focuses attention on the efficiency of that system because low values of energy efficiency mean the existence of high potentials for saving energy consumption. Since the share of fossil fuel consumption in pistachio processing is a significant share and the most fuel consumption is done by dryers, therefore, in this article, the issue of energy consumption in pistachio dryers is discussed.

Pistachio drying process

Drying pistachios is considered as one of the most important processing steps of this product. During this process, pistachio moisture should be reduced from 25-35% based on fresh weight to less than 5% so that the product can be stored properly and does not suffer from spoilage and mold. The dried product can be stored under normal conditions for up to one year or more. The main purpose of drying is to prevent spoilage and contamination of the product and increase its shelf life. In drying agricultural products, what is common in all cases and all methods is heat transfer ) supplying heat that must be given to the product to evaporate water( and material transfer )removing water and water vapor from the product and its surroundings( Therefore, it is desirable to have a method and a device that makes these two things easier and speeds up the drying process with low energy consumption .

Different methods of drying pistachios

Pistachios can be dried in various ways, including :

1- Sunny field 2- Aeration using ambient air )non-hot air( 3- Hot air )dryer( 4- Two stages which are done in two ways: A- Hot air and then a short period of aeration with ambient air and then From that sunny field, B:Using warm air and then aeration with ambient air .

Drying in the sun

In this method, pistachios are spread separately on cement or mosaic fields and dried under the sun and with ambient air. Although drying by the sun does not require energy, but in order to achieve the desired result from drying in the sun field, all sanitary and technical points must be observed. Sometimes, due to the insufficient temperature and earlier collection of the product from the field, the pistachios do not reach the safe moisture level and the aflatoxin-producing fungi get a chance to work. Also, if the volume of the processed product is large, this method does not work at all. It can be an answer unless we can dedicate more cement fields to this work, which is expensive and practically impossible for high-capacity processing units. Spreading, stirring and collecting requires a lot of labor.

Drying in the dryer

After the dehumidification process, the humidity of the pistachios is brought to about 10% by blowing hot air through the dryer. In fully mechanized systems, for final drying and uniformity of humidity, the product is aerated in the dryer by turning off the heat source or in large silos using ambient (non-heated) air until the humidity reaches less than 5%. . In the semi-mechanized drying method, after the pistachio moisture reaches 10%, they are aerated for a short time using ambient air and then transferred from the dryer to the sunny field.

Heating is provided by the burning of fossil fuels, gas and diesel, which is either ignited in the combustion chamber and then its heat is transferred to the pistachios by the air flow supplied by the fan, or it is in the form of a direct flame. In the direct flame type, it is difficult to control the temperature on a specific number because environmental factors prevent the temperature from being fixed on a number, and a temperature controller must be used in these systems. In dryers with a combustion chamber, the areas around the chamber must be completely insulated, and the heat from the exhaust must be used for reuse in the dryer. In some tests, it has been determined that the temperature of the exhaust outlet was 312 degrees Celsius and the temperature of the body of the combustion chamber was 126 degrees Celsius, while the temperature received by the pistachios was reported to be 57 degrees Celsius, and this indicates the loss of energy from the system.

Classification of dryers

-

Wagon dryer

The wagon dryer has a fan, oven, channel and wagons similar to Farghun

. The bottom of the wagons is made of a grid plate, this plate is located on a chamber with variable depth. The wagons are connected to the channel by a tarpaulin or a clamped metal interface. Hot air is blown into the pistachio from inside the channel and through the holes of the mesh screen. These dryers are made in four and eight wagon types. The eight-wagon type of these dryers has the capacity to dry 2100 kg of pistachios with a depth of 18 cm. One of the disadvantages of these types of dryers is that the process requires labor to stir the product and the possibility of physical damage to the product and Also, it is not possible to obtain a uniform moisture level of pistachios .

The process of the product is discontinuous and this type of dryer has a good separation ability, that is, different varieties of rum can be dried without mixing together. They are available in two types, gas-burning and diesel-burning, and their fuel consumption is high, and if we want to use the direct flame type, only the gas-burning type has this capability, and due to the sudden changes in the temperature of the hot air, we must use a thermoregulator or a digital thermometer. as well as gas control valve (electric or manual) to set the amount of fuel. This type of dryer takes up a lot of space, and if we have a lot of products for processing, a lot of space should be considered for placing this dryer .

2- continuous double wall vertical dryer

In this method, the pistachio is located between the two inner and outer walls of the machine and is pushed down using gravity. The walls are mesh and hot air is blown to the products through the central space of the inner wall and is directed out through the outer wall .Usually, two machines of this dryer are placed next to each other in series, and pistachios enter the other after leaving one. This dryer does not need a worker. The space requirement of this type of dryer is low and energy consumption is optimal. In Iran, the problem of maintaining the uniformity of drying different layers in this technology has not been well resolved. This drying method is done in California due to the single digit of the American pistachio (Kerman ) , because if we have different digits, it is not possible to use this dryer due to the mixing of the digits. In case of using this type of dryer, if the amount of product is less compared to the capacity of the dryer, we should use the shared processing method or buy more .

3- Intermittent vertical cylindrical dryer

In this method, as in the previous case, the product is inserted between the walls of two overlapping cylinders, the radius of one of which is about 25 cm less than the other, and it can use the force of gravity to move the wall from below during drying time. Among the defects of this type of dryers, we can point out the impossibility of drying different varieties of pistachios continuously, although currently this type of dryer is not used in pistachio processing centers .

4- Continuous dryer with conveyor belt

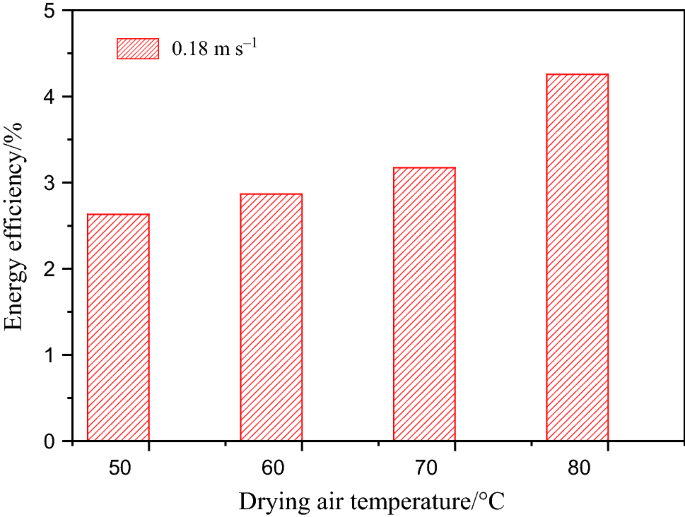

In this type of dryer, the product passes through a mesh conveyor belt, where hot air is blown from below to the product. Paddles may facilitate the movement of pistachios forward. This type of dryer is made with a length of 22 meters and a width of 2.5 meters, and three heat sources that provide temperatures of 80, 70 and 60 are placed along the length of the dryer .

To provide the required temperature of this type of dryer, burning gas or diesel is used, and the calculation of its energy efficiency needs more research. It does not have a good product separation capability and is not suitable for low capacities. The space occupied by this dryer is not too much. For continuous drying, two silos must be used, one before the dryer to adjust the feed and create a steady flow of pistachios into the dryer, and the other is a silo that aerates the pistachios )by ambient air( and is placed after the dryer .

Important indicators in pistachio drying process

- Changing the parameters of temperature and air flow speed has a significant effect on the duration and efficiency of pistachio drying and the quality properties of dried pistachios, so that with the increase in temperature, the amount of sugar increases and the number of free kernels increases

- In drying pistachios by aeration method, spots on the skin, amount of aflatoxin and drying time are influenced by factors such as pistachio accumulation depth, speed of air blown into pistachios and drying temperature .

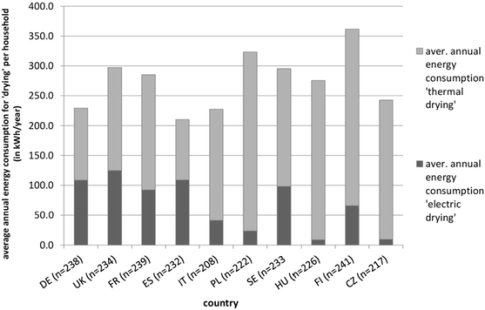

Effect of aeration rate and comparison of aeration energy in different methods

Increasing the speed of blown air to an optimal level reduces the drying time, but if we increase the speed of hot air too much, the air leaves the dryer system without being saturated with moisture, which has a high degree of energy loss .

The research conducted in the United States, the data obtained from which is in accordance with the weather conditions there, showed that pistachios were stored at depths of 45, 90 and 137 cm using the aeration method with a wind speed of 0.36 and 0.51 m in seconds dried in the same amount of time, but moisture loss was significantly slower at an air velocity of 0.2 m/s. According to the results, in the aeration method )with ambient air(, the appropriate value of the air flow speed is 0.36 meters per second, and a higher aeration speed has very little effect on accelerating the drying process. The comparison of the energy cost related to different speeds also revealed that the cost of energy consumed at a speed of 0.36 m/s is half of the speed of 0.51 m/s, while they are not different in terms of reducing the drying time .

The effect of fuel consumption and comparison of thermal energy in different methods

Data obtained from research conducted in the state of California, USA, show that the use of temperatures higher than 71 degrees Celsius )which is usually used by processors( significantly reduces the time and cost of pistachio drying. reduces so that the amount of energy consumption at temperatures of 93 to 138 degrees Celsius is almost half of the energy used at temperatures of 71 degrees Celsius . The evaluation of the quality of dried pistachio seeds at different temperatures shows that the temperature of 93°C has no harmful effect on the pistachios except for the increase in the number of free kernels, but the taste of roasting at temperatures of 115.5 and 138°C was recognizable.

User comments